Discover how RACO electric actuators are utilized for lock bar systems for bridge construction.

RACO Submersible Actuator: A Comprehensive Overview

RACO's Role in Submersible Actuator Applications

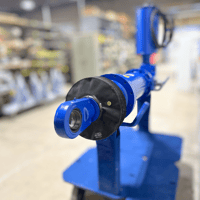

The RACO Submersible Actuator has been carefully designed to operate in areas prone to flooding or water immersion. This innovation was inspired by the specific requirements of a low-lying movable railroad bridge that often experiences flooding. RACO created an actuator that can be fully submerged in up to 8 feet of water. RACO successfully modified MA Style Actuators to meet the demands of this environment. These actuators only need to withstand submersion and are not required to operate during flood conditions.

Design and Modifications

To meet the rigorous demands of submersion, significant modifications have been implemented across the MA Style Actuators. These enhancements include:

-

Watertight Protective Cover: A critical modification is the watertight cover over the gearmotor with brake assembly and end of stroke limit switch device. This cover prevents water ingress, safeguarding the gearmotor and electronic position sensor. It also features connection points for power and motor control cables.

-

SEOOW Power Cable: Designed to endure submersion, this cable ensures reliable power delivery under water.

-

IP68 Sealed Control Cable: The control cable features a sealed IP68 plug and socket, interfacing with the electronic position sensor. The socket employs multiple o-rings, sealing gaskets, and locking rings to prevent water penetration, allowing for electronic limit switch adjustments without removing the protective cover.

-

Seaside Protection Package: This package includes Macropoxy Marine Duty Paint for external corrosion resistance and an internal coating on the shield tube to combat internal condensation. Metal-to-metal joints are sealed with a special sealant, and nickel-plated liquid-tight strain relief fittings ensure IP68 watertight integrity.

-

Front Cap Seals and Dirt/Ice Wiper: The front cap utilizes multiple seals and a dirt/ice wiper, featuring a metal housing with an integral brass scraper and NBR wiper ring to remove contaminants effectively.

-

Spherical Rod End/ Clevis and Trunnion Brackets: The rod end is maintenance-free with permanently lubricated components. The trunnion brackets include an anti-seize bushing for free pivoting without lubricants, maintaining functionality even when submerged.

.png?width=776&height=776&name=Your%20paragraph%20text%20(4).png)

Application specifications

Currently, the RACO Submersible Package has been offered in four sizes of the MA Style Actuator: Sizes 4, 5, 8, and 10. These packages can be customized for any MA Series Actuator to meet the specifications of your application.

-

RACO Size 4: Features a self-locking ACME Screw with an 11.8-inch stroke, driven by a parallel gearmotor. It offers a nominal thrust of 1,100lbs and a maximum thrust of 1,600lbs at a rod speed of 0.7 in/sec, used for centering latches.

-

RACO Size 5: Also equipped with a self-locking ACME Screw and an 11.8-inch stroke, this actuator provides a nominal thrust of 2,200lbs and a maximum thrust of 3,300lbs at a rod speed of 0.7 in/sec, used for rail joints.

-

RACO Size 8: With a 15.7-inch stroke and a self-locking ACME Screw, it delivers a nominal thrust of 17,600lbs and a maximum thrust of 26,000lbs at a rod speed of 0.5 in/sec, used for center wedges.

-

RACO Size 10: This actuator features a precision ground ball-screw with a 23.6-inch stroke, driven by an offset parallel gearmotor. It provides a nominal thrust of 66,000lbs and a maximum thrust of 100,000lbs at a rod speed of 0.5 in/sec, used for end wedges.

Conclusion

The RACO Submersible Actuator marks a major leap forward in the field of actuator technology, providing exceptional performance and unwavering reliability even in environments susceptible to flooding. This innovative device is equipped with specialized modifications and a suite of comprehensive protection features that guarantee its continued operation and long-lasting durability. It is specifically designed to meet the rigorous demands of critical infrastructure applications, ensuring that essential systems remain functional and efficient under challenging conditions. By integrating advanced engineering and cutting-edge technology, the RACO Submersible Actuator stands out as a vital component for maintaining the integrity and resilience of infrastructure in flood-prone areas.

Subscribe Here!