Steel Water Engineering

Actuation of a Pivoting Bridge

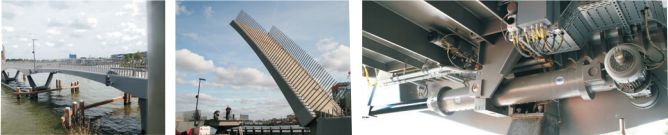

RACO electric actuator employment in hydro mechanical engineering steelwork - Actuation of a pivoting bridge segment by means of two electric actuators in synchronization

RACO electric actuators are used for flap bridges for movement and interlocking. The scope of delivery of the company RACO includes both the electric cylinders for the bridge drives, as well as the RACOmatic e.g. for synchronizing circuit, as well as the project planning. The movement profiles for the opening and closing of the flap bridge can be programmed individually and control-activated in optional operating modes. The RACOmatic for the synchronizing circuit includes a micro-PLC, which can also be used as a local control. In the same way, a manual control of every electric cylinder is possible in order to carry out an adjustment in the tolerance range.

Ref. the project:

The control of the entire flap bridge system, including the traffic lights etc., is implemented video-monitored from the central control room of the City of Amsterdam. Over a hotline, the opening of the bridge and thus access to the "City Marina" port can be requested. For the application of the "drive command" for the actuation of the movable bridge segment, the synchronizing circuit for the two electric cylinders is provided, which can also be used as local control.

- The security concept provides that one electric cylinder alone can hold the bridge segment. By the venting of the retention brake, an electric actuator can be "dragged" by the second electric actuator and thus the bridge segment can be driven with reduced speed in an emergency

- The load-change reactions with wind load in the opened, vertical setting of the bridge segment are a further boundary condition. This determines an increased brake torque of the electro-magnetic brake on each electric actuator which is adapted to the wind load.

- The synchronizing circuit for the two electric actuator is capable of being used autonomously as a local control and of control-activating each electric actuator separately in an emergency.

- The distortion of the steel structure with fluctuating ambient temperatures is compensated by a force-monitored control activation for the placement of the bridge segment on the opposite bank.

- The sea climate places high demands on corrosion protection and the ceramic coating of the sleeve.

RACO concept / function:

In order to balance the tolerances in the steel structure, the

In order to balance the tolerances in the steel structure, the

In this way the maximum regulating speed is exploited during opening of the bridge over the entire lift. The "park position" of the bridge segment in the open setting is freely optional within a range. The low-play, precision-ground ball screw drive from RACO is the core of the electro-cylinder. This can take up the resulting load-change reactions. During closing of the bridge, the aspect "safe switch-off" of the electric cylinders is especially important in the position where the bridge segment has reached the support point on the opposite bank. This is achieved over the RACO torque control system, which is active in creep motion prior to reaching the support point.

We are the linear motion people

RACO International, L.P. is located in Bethel Park, PA and serves the needs of customers in the USA, Canada, and Mexico. This includes primarily the sales and manufacturing of customized solutions and services of products to their customers, as well as supporting its customer base with part sales and repairs. Please contact RACO in Bethel Park, PA with any application questions.

.png?height=200&name=Untitled%20design%20(62).png)