Steel Water Engineering

Gates

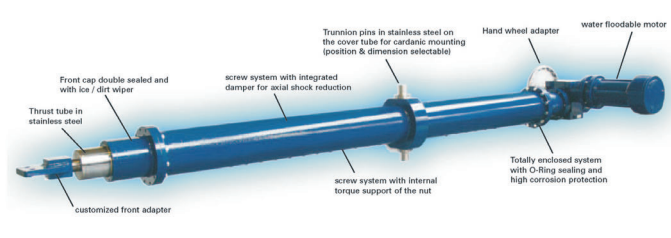

RACO electric actuators Application: Moving Two mitre-gates in a Canal lock

The mitre-gate is designed as an open gate in steel water engineering and serves as a protection mechanism of the vertical gate in the lock system. The actuation of every gate wing is implemented by means of a RACO Electric Actuator, which is supported horizontally in an adapted cardan mechanism. The area in which the electric cylinders are located can also be overflowed in case of high tide water.

Requirements:

- The utilization duration of the electric actuators is planed for 30 years.

- The electric actuators are equipped with submersible motors, including holding brake with an sealed housing

in protection class IP68. - The push-pull unit requires a sealing system which statically seals up to a water column of 5 meters above the

electric cylinder for at least 72 hours, thus preventing water ingress. - In case of a voltage failure, the electric cylinders can be activated manually

- Axial impact loads which act on the rod should be absorbed by an internal cylinder shock damper.

- Corrosion protection by being attentive to the selection of materials, stainless steel sleeves, and a paint coating system meeting standard DIN EN 12944-2.

RACO Solution:

For this application, two RACO type K1R9 electric actuators of the type K1R9 were selected. Each had a stroke of more than 3 meters in each case. Both electric actuators are control-activated separately to the programmed final positions using a PLC control. In addition, manual control of each electric actuator via a hand wheel was possible. The retention brake is mechanically released for this purpose and simultaneously the start-up of the motor is interlocked.

The RACO electric actuators for hydro mechanical engineering steelwork applications, specifically, come with a vent valve that encloses the volume in the interior of the cylinder at standstill and thus does not allow any exchange with the environment. The background is the so-called air-pump effect, which is implemented using a design type with electric cylinders through the change of volume during actuation movement.

For project construction work of this magnitude, the design requirements concerning the period of use should be at least 30 years. In addition, full detail to the site and application safety factors was necessary, with attention to corrosion protection being critical. The coating systems used by RACO come from certified manufacturers and are professionally processed with the greatest care.

RACO is your system supplier for hydraulic engineering steelwork applications

Equipment packages for "on-shore" and "off-shore" applications further include a great number of measures for corrosion protection (EN ISO 12944-2, C5 M). In some instances, even the protection conditions according to EN 60529 IP65 or higher must be fulfilled. Enclosing RACO electric actuator systems with "Long-life lubrication", yields minimum maintenance intervals with a maximum service life.

Interlocks for various bridges have been one of the numerous solutions from our company over many decades. The installation-ready, electromechanical-actuator systems position exactly and hold flood backup flaps, gates and sliders in their planned setting, even with extreme weather. As RACO cylinders are suitable for use in ambient temperatures from -20°C to +70°C.

We are the linear motion people

RACO International, L.P. is located in Bethel Park, PA and serves the needs of customers in the USA, Canada, and Mexico. This includes primarily the sales and manufacturing of customized solutions and services of products to their customers, as well as supporting its customer base with part sales and repairs. Please contact RACO in Bethel Park, PA with any application questions.

.png?height=200&name=Untitled%20design%20(62).png)